Today, more and more consumers, when performing finishing work, choose PVC and MDF panels, since this is a very practical option, affordable for almost everyone, and all installation work can be done independently, also significantly saving. But all the leading positions are rightfully occupied by PVC panels for walls, as they are resistant to a humid environment and aggressive detergents, as well as temperature extremes. This means that this is an ideal option for lining bathrooms and toilets, pools, as well as rooms with non-constant heating. They significantly speed up the repair process, making it cheaper, and the variety of color ornaments and sizes contributes to the fact that the finishing stage of the work can be carried out practically without unnecessary waste of material, choosing decorative sheet panels or flexible PVC panels taking into account all the features and sizes of the room.

PVC wall panels in the interior of a modern bathroom

What are PVC panels

This version of the panels is made of polyvinyl chloride with the addition of 57% particles of chlorine, 43% ethylene. Lead is used as a binder. The material is sufficiently rigid, which gives it the desired strength, but at the same time flexibility. Bringing the mass to a liquid-like state, it is poured into special forms of a certain size. After cooling down, a pattern is applied to the PVC panel, or it is printed on a film, which is subsequently glued to the front surface of the PVC panels. In addition, the panel can have a different color scheme, imitating natural materials, for example, it can be a wood-fiber structure or a structure of stones of natural origin. Also, the differences between the PVC panels are in the texture, i.e. the surface can be smooth and varnished, or embossed and convex, imitating, for example, a mosaic. In addition, PVC wall panels are produced as ceiling panels. Odor products during operation does not emit.

Types of PVC panels

What to choose a panel from PVC or MDF

When wall or ceiling paneling, the question often arises which types of panels to choose to finish repairs as soon as possible, what they should be made of in order to have better environmental properties, which panels are better than MDF or PVC. There is no way to unequivocally answer the question posed, since each type of panel has its own number of advantages. Both PVC and MDF panels for interior wall decoration are just perfect. Their fixation method is approximately the same. Repairing the sheathing of walls and ceilings with these materials can be done on their own without resorting to calling masters, this is an undoubted plus. During operation, the materials do not emit an odor harmful to humans. The design is very diverse, and both options are good in their own way. For example, MDF panels perfectly imitate the wood structure, and PVC panels can be sheathed arched openings. At the same time, MDF panels are completely unsuitable for covering the arch, since they do not have the necessary properties to bend and do not withstand a humid environment, their service life in this case is reduced significantly. That is why the most positive aspects, according to most consumers, have panels based on polyvinyl chloride. But it is unambiguous to say what is better, and what type of PVC or MDF panels to choose, it is impossible without having tested both options in action.

Properties of PVC panels

Only by knowing the properties and features, it will be possible to clearly answer the question, what is a PVC panel, and what positive aspects does it have:

- The panels have a high service life exceeding the service life of more than 50 years,

- Easy surface care - no special detergents needed

- A variety of sizes, it can be plates or PVC sheet panels, of different lengths and widths, the thickness can also vary. Varieties of panels differ in color,

- The temperature of their operation can be different, they are perfectly adapted to its differences,

- Installation can be done with your own hands, this does not require a specific tool and special knowledge and skills. In case of deformation, they can easily be repaired independently,

- Suitable for cladding in damp rooms, not prone to mold and mildew,

- Before installation, alignment of working areas is not required, therefore, there is a saving in cash costs. Installation is carried out in this case on a pre-prepared frame, where you can hide all the electrical cables,

- PVC panels can be wall and ceiling, their types are very diverse. It’s convenient to sheathe not only living quarters, such as hallways, corridors, living rooms, but also balconies, pantries, bathrooms and toilets, and kitchens. The material of their manufacture is quite rigid, but it is easily bent. Thanks to this, the corners, as well as the arch and arched openings, in the presence of a panel of the required number of meters, can be made completely seamless,

- PVC panels have quite significant sound - and thermal insulation properties,

- In the production of these products, GOST is strictly adhered to and all are environmentally friendly, so you can safely answer the question whether they are harmful, the answer is negative,

- It can be emphasized that every 3rd repair can not do without the use of PVC wall panels or ceiling, because they have a very reasonable cost.

There are almost no disadvantages of PVC panels. Unless their use in fire hazardous premises is overgrown, since during burning they melt and can give off a rather unpleasant odor. Another smell is possible during installation: when cutting panels of the right size with an electric jigsaw or a high-power grinder. It is recommended that this work be done with a protective mask and goggles. Subject to these safety measures, they do not cause any harm to human health.

If you nevertheless need to use this product in the immediate vicinity of the fire source, it is recommended to give preference to panels made of denser and harder plastic, they are thicker, but at the same time they have standard sizes and can be produced as sheet panels for walls and ceilings or rectangular.

PVC panels in a modern interior

Dimensions

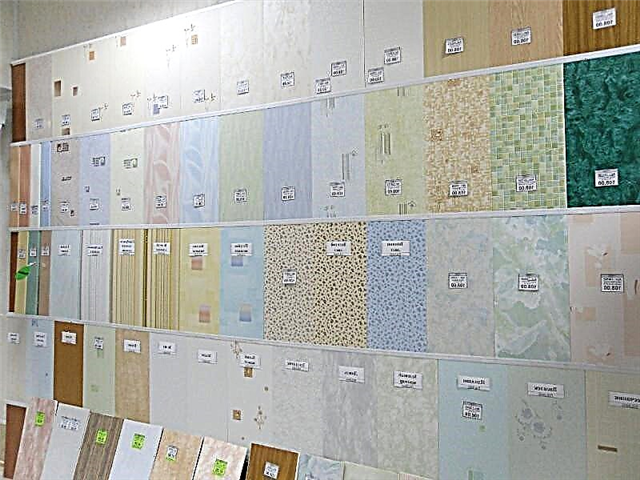

Construction stores offer a wide range of PVC panels with different sizes and colors. They are all made according to a single principle. But in order to visualize them in the interior, it is recommended to attend exhibitions and not to ignore the exhibition hall in construction stores. A wide range of panels is presented there, differing in their sizes, they can be in the form of PVC sheet panels or rectangular or even square.

The main dimensions of the panels

| Width (mm) | Length (mm) | Thickness (mm) | Panel Type |

|---|---|---|---|

| 250 | 2700 | 8 | leafy |

| 250 | 2700 | 9 | leafy |

| 100 | 2700 | 3 | leafy |

| 250 | 3000 | 7 | leafy |

| 375 | 6000 | 3 | leafy |

| 950 | 480 | 3 | rectangular |

| 950 | 650 | 8 | rectangular |

| 300 | 300 | 3 | square |

| 980 | 980 | 8 | square |

It is worth noting that sheet panels are more flexible, flexible, soft and pliable in work, this is an indispensable material for arch work, which greatly simplifies repair, since all this can be done with your own hands. To give the panel the desired bend, sheet panels for interior decoration are required. You should choose a plastic material, the width of which is small and the thickness is thinner than that of rectangular models of PVC panels. The panel must be brought for 10-12 hours in a warm room, in close proximity to a heat source. Due to the thin plastic with little heating, the material can be easily bent into an arcuate string.

The average thickness of the PVC sheet panel is 4-8 mm, but to create a bend it is better to give preference to panels with a thinner thickness. Due to its flexibility, sheet wall panels for interior decoration have become a godsend for rounding. Of course, only an experienced specialist in this field will tell you how to sheathe an arched doorway with PVC panels and how to bend a large panel correctly and still not damage it.

PVC sheet panels

PVC Square Panels

The height of the ceiling dictates its conditions, what types of panels are worth choosing. The sheet panel is indispensable for the lining of rooms with high ceilings. Often, the length of the panel allows you to lie in a single even cloth from the ceiling to the floor. Carrying out repairs in small rooms, for example, when lining PVC panels in bathrooms, it is worth giving preference to rectangular or square models. There will be much less material waste, and it will be easier to work.

Rectangular PVC Panels

The range of panels in the construction industry is striking in its scale. It can be MDF or PVC panels, wood panels. Each of them has its own technical characteristics, thanks to which the consumer makes a choice in favor of a particular model. Modern materials used in the manufacture of PVC panels do not emit any smell at all, they come in different sizes, wider and narrower, with very small sizes to create separate compositions. Panels for interior wall decoration can be made of thin and soft plastic, which does not smell at all. But the biggest factor influencing the choice is the price, which sometimes differs significantly depending on the type of panel.

Properties and characteristics

The composition of PVC panels includes polyvinyl chloride, which is a light and high-quality material. Due to this, the ceilings in rooms, in offices and in supermarkets are often upholstered with these panels. Also, PVC panels depict an interesting pattern using lamination, thermal printing and other modern technologies. After that, a matte or glossy varnish is applied to this material, which is a protection for the material.

Thanks to this treatment, the panel does not lend itself to rapid wear and is very resistant to ultraviolet rays, as well as any damage, for example, is protected from scratches. For the safety of the health of a person and his family, harmful chemical components are not used in the production of such polyvinyl chloride panels. Also, when painting surfaces, coloring agents are used only on a water basis, which is also absolutely safe.

There is a difference between the plastic panels used on walls and ceilings. It lies in the fact that the wall options are a little stronger, and they are not flexible, so such panels are able to withstand heavy mechanical loads. Also options for walls are thicker than for ceilings. The more polyvinyl chloride, the thicker the panel. The stiffeners located inside the wall PVC panels have a thickness of 1 mm, so cutting them with a knife will not be so easy.

The length of this material is 3 meters, the width is only 10 cm, and sometimes it can even reach 12.5 cm. Plastic lining can be used for both external and internal processing of premises. In total, two types of this material have become popular on the market. These are “polka” and “european”. The "polka" has a small castle connection, while the "european" it is much wider.

Exterior PVC panels have a seam. This is due to the fact that the material has a high coefficient of linear expansion. Therefore, the lining, which was not mounted indoors, must change from a change in temperature conditions. There is also another feature of facade clapboard. It lies in the fact that the coloring of raw materials in different colors occurs even during production, and is not applied from above as in other types. Because of this, the lining keeps its initial color longer.

Sheet panels made of plastic have a width greater than that of a plastic lining. Their length is from 105 to 405 cm. These panels are the most famous and consumed. Sometimes the surface of the sheets is sent for special processing, but not all do it, but only some good manufacturers. Thanks to this operation, the panels become more durable and stable.

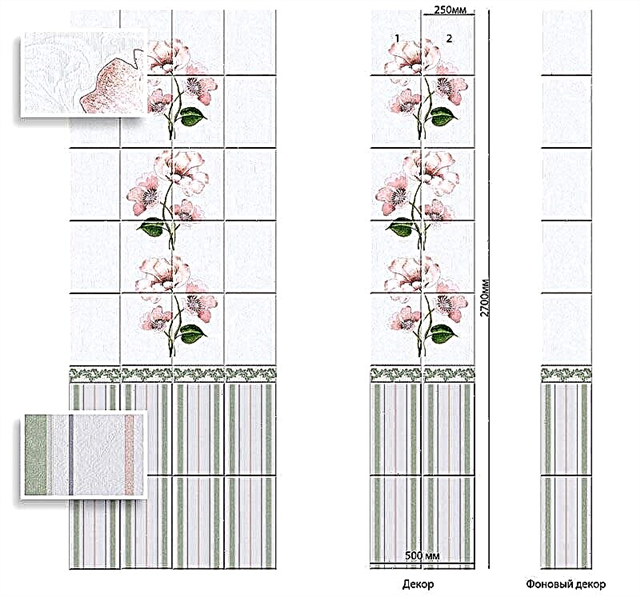

Glue and nails can mount sheet panels. Slots can be sealed with a sealant of the corresponding color or with a narrow rail. Conventional panels have a length of 260 and 270 cm, sometimes even 300 cm, and a width of about 25 cm. But you can also use panels with a width of 50 cm for decoration. The side of the outer surface, lacquered and painted with paint, also forms a seam, which is not very noticeable when it acquires an assembled look.

There are also a GOST PVC sandwich panel, which are modern and highly exploited. A feature of these panels is the presence of two sheets of plastic. Polyurethane foam or expanded polystyrene foam is used as various added substances, they give the material heat-insulating properties. The combustibility of the products is indicated on the package. The largest coefficient has a plastic lining.

Advantages and disadvantages

This material has become so popular due to the large number of advantages.

- Universality. Usually, PVC panels are used as walls and ceilings. This material can be used to decorate the edges of doors and windows, used in the shower and bath, also under the steps to create interesting shapes. Summer residents this building material is used to form garden beds.

- Installation is quick and easy. Ordinary homeowners can now decorate a wall or some other surface. Work is quick and easy with smooth walls or ceilings. In such situations, they are fixed with "liquid nails." To make curved surfaces more even, it is worth using a metal or wooden frame.

- Easy to care for. PVC panels can be cleaned with a normal soapy cloth, but you should beware of panel joints, because these places are weak.

- Such panels are absolutely eco-friendly. This material is non-toxic, does not emit harmful substances into the environment.

- Strength. This indicator depends on the right choice. For ceilings, this material is a bit lighter.

- There is sound and heat insulation. These panels create good sound insulation and do not allow cold to enter the room.

- A large number of colors and shades. The standard color of PVC is white, but manufacturers have created a huge number of colors for every taste of the consumer. At the moment, panels with drawings or with imitation of the texture of stone or wood are popular.

- Moisture resistant. Due to their flat surface, they do not retain moisture. Since there are no pores on the material, dirt, mold and other harmful microorganisms do not linger on its surface. Therefore, they are often used in rooms where humidity is high.

- Resistance to sharp changes in temperature. Plastic panels can withstand temperatures from -50 to +50 degrees Celsius.

Like other building materials, PVC panels have disadvantages.

- Instability to ultraviolet rays. White plastic panels after a certain period of time may turn yellow and lose their original appearance.

- Instability to blows. Such panels can withstand some loads, but they are not protected from dents or scratches on the surface of the material.

- The composition of the material contains chalk, which is a determining component of the strength of the product. The amount of chalk in the panels is determined solely by the manufacturer.

- Characteristic smell.When buying and using panels for a few days there is a specific smell, but then it completely disappears.

- This plastic cannot be called absolutely safe, as many manufacturers claim. It should not be used to design children's rooms.

Varieties and applications

At the moment, three types of PVC panels have gained popularity in the building materials market.

- Rack and pinion. To attach this type of panels directly to the wall surface, you must use a metal bracket. This panel has a length of 1 to 12.5 meters, a width of 15 to 30 centimeters, and a thickness of not more than 1 centimeter. If you use this view to decorate a room, it will visually look higher or lower, depending on the position of the panels themselves.

- Under the tile. The sizes of this species can be from 30 cm to 1 meter. The way to decorate the room is the same as that of the rack panels, but differs in its result. Such PVC panels can be laid out with an interesting pattern in the bathroom or in the kitchen.

- Leafy. These panels are recognized as the best of all the above types. To install this material on a wall or ceiling, you will need glue and nails. The thickness of the sheet panels is from 3 to 6 millimeters.

Also, PVC panels can be divided by decorativeness.

- Seamless. Such panels are very popular and look expensive. Seamless panels with a matte finish look great. They are for both floor and furniture.

- Embossed. They look exactly like wooden ones, but their price is much lower. However, they can be used even if the walls have a certain curvature. Embossed laminated panels offer a very accurate imitation of textures.

There are also several types of panels depending on the design.

- Plain. They are ideal for interior decoration where practicality and minimalism are appreciated. To give a one-color solution to originality and beauty, you can independently make multi-colored shelves or use paintings.

- With drawing. Such panels often imitate the appearance of stone or fabric, but there are also those that attract attention with a spectacular print, for example, clouds. But difficulties may arise during their installation, since it will be necessary to accurately calculate their position, then the drawing will turn out to be solid.

They use PVC panels in bathrooms, in showers, in the kitchen, and they are often used to decorate offices, restaurants, supermarkets, schools, gyms, hospitals and other rooms.

These products are universal, so they can be used even in unusual places, for example, gardeners use this material in gardens. Also, with their help, you can create an original interior. They are environmentally friendly.

Manufacturers

It is very important to choose a good manufacturer before starting work. In order not to be disappointed in the quality of the building material, you should get acquainted with the main manufacturing companies that produce a quality product, they have mostly only positive reviews.

The following manufacturers are in great demand:

- Racoon Plastik,

- Polimerpanel,

- Pareti,

- BellerPlast,

- Plastek

- Plast Decor

- KronaPlast

- Aquaton.

Criterias of choice

When buying PVC panels, you should pay attention to the cost of goods. The higher the price, the better the product.

In order not to be mistaken in the choice and not to be deceived, it is worth familiarizing yourself with some points of purchase.

- Required panel thickness. The universal thickness of vinyl for walls should not exceed 10 mm, and if you need to choose a building material for the ceiling, you should pay attention to a thinner one.

- The strength of the front surface. This is important and necessary so that the building material can withstand damage and shock, and at the same time there are no dents or scratches on it. If stiffening ribs are visible from the outside, then such panels are best not to be used for wall lining. It is better to apply them to ceilings, but such work will not look very good and of high quality.

- The number of edges, their position and stiffness. The rigidity of the building material is very much dependent on the number of edges itself. The largest distance that may be between them should not exceed 10 mm.

If during transportation the ribs wrinkled a little, lost their shape, then in these places dents will be clearly visible.

- The uniformity of the coating of the surface of the material with paint indicates how the paint was applied to the panel. Most manufacturers cover the surface on the front side, instead of adding an element that gives color to the polymer composition. This is bad because during work with the material the paint can easily peel off the surface. Also, due to such a coating, the PVC panel may burn out, and the paint will be unevenly located, which is another drawback of this manufacturer's work.

- When buying building material in a store, you need to ask about its weight. This can help determine the stiffness of the ribs and the wall thickness of the material. The optimal weight of PVC panels should be 1.1–1.5 kg / sq. m

- Are the panels firmly connected? It is better to check the strength of the connection of PVC panels during the examination of the goods.

- How many percent of the chalk contains material. Many professionals claim that the percentage of chalk in the product should not exceed 20%. If this percentage is higher, then there is a high probability that this material is quite fragile. Chalk is very affordable and not expensive, so some manufacturers add more than required by the standards to reduce the cost of their products. By bending the corner of the product, you can check the amount of chalk in it. If there is no white strip on the plastic, the panel contains the desired amount of chalk.

- Panels containing toxins. It's okay if the sealed lining has a characteristic, but not too sharp smell. But if a specific smell comes from panels that are exposed as a sample, it immediately becomes clear that this material contains toxic substances and it is better not to get it.

- Brand If the product is from a well-known seller, then there is a good chance that the material is of fairly good quality. Indeed, in order to earn such fame, the manufacturer worked for a long time on the quality of his goods, and values his reputation, therefore, he offers only high-quality products for wall and floor use.

- Decor products. Facing panels must be thermo-transfer. They belong to the economy class. Thanks to thermal printing, you can choose a different decor. The picture is not afraid of the effects of ultraviolet radiation, and also does not erase with time. Variants with frieze are in demand, as they are decorated with various prints. Typically, such products mimic the surface of marble, tile or natural wood.

Models made of MDF have much in common with PVC panels, so when choosing them, you can also use the above selection criteria.

Installation and work tips

First you need to prepare for the work itself. Before installation, there is no need for special preparation of the walls. But you need to very accurately measure the surface that will be finished, and also accurately calculate the number of panels. You also need to decide how the installation will be carried out.

If the ceilings and walls are flat, have no errors, then the panels can be glued. But if you need to give the room even parameters, then it is better to assemble the frame. In this way, the rooms will have an aesthetic appearance, and all the bumps on the surface will be hidden and invisible.

To work, you need tools such as:

- step ladder,

- drill,

- hacksaw for metal,

- roulette,

- knife,

- self-tapping screws

- hammer.

All these items must be purchased before starting work. As soon as all the tools are on hand, you can begin work. Usually, 100 mm wide panels are used for ceiling installation. It is better to measure the lines in 0.4 m. To begin with, it is worth noting the lowest point on the ceiling and from it put marks that will be equal to the width of the panel. Then you need to mark the points where the anchor or dowel will be installed, which are important for attaching the frame.

The frame must be placed perpendicular to the fastening panels. For ease of marking, professionals advise stretching a thin cord instead of marks. To use it, you need to rub the cord with colored chalk and attach it to the marked wall. After this procedure, a clearly visible mark will remain on the surface.

For the finish to be of high quality, the correct assembly of the frame, which is similar to the connection of profiles, is necessary.

PVC panels: applications

This finishing material is universal. It is used in rooms with normal or high humidity, for walls or ceilings. The only limitation of use is the lowered temperature - in the cold, PVC becomes brittle and breaks with little physical impact.

Finishing the bathroom and the bathroom with plastic is simple. At the same time, flaws are hidden, uneven walls. You can also hide the sticking pipes of water supply or sewage - in this case you will have to assemble a box from a metal profile or a frame from a bar.

Artificial PVC sheet panels are suitable for an apron in the sink, work area in the kitchen. These are glued to the wall and do not require a frame device. They wash easily enough, but do not tolerate the use of abrasive cleaners.

Separation of PVC panels as intended

Such decorative materials can be conditionally divided into ceiling and wall. The question arises - why "conditionally"? But because the home master decides for what purposes to use them. Ceiling panels look good on walls and vice versa.

However, there is a slight difference in the strength of the products. Thin and brittle plastic is used for the ceiling, coarser, more rigid for walls. But if you do not plan to hit the walls with your fist or lean on it, this difference is not significant.

Separation of species by connection method

Here the division is clearer. The following products are distinguished:

- Seamless. Perfect smoothness, as with stretch ceilings or drywall, can not be achieved, but the surface will be flat, with barely noticeable joints. The problem here may be improper storage and transportation. Then the products will be bent, and docking them perfectly is unlikely to succeed. Paying attention to the packaging method (front to front), you can choose panels curved in one direction (through one), thereby achieving a minimum discrepancy,

- Embossed. This type is made under the "lining". Used in the case of seasonal "swimming" of the building. With relief joints, slight discrepancies are not noticeable. Such a finishing material does not have an average price category. These are either expensive or cheap products,

- Rusty. This is a compromise between seamless and embossed products. It turns out that if you remove the chamfer from the seamless panel, you get rusty ones.

We offer for acquaintance photos of PVC panels with various types of joints:

Seamless products in the interior

Seamless products in the interior

PVC wall and ceiling panels: properties, advantages and disadvantages

The main advantage of PVC panels is the price - there are no competitors in this parameter. It is worth noting the vapor and water tightness, which allows the installation of such material in the bathroom or kitchen. Durability is beyond doubt - in the absence of mechanical impact, this parameter is 50 ÷ 70 years. Installing plastic panels is simple - a home master can easily do this without experience in such work. Plastic is also resistant to liquid detergents or gel-based products.

But you can not ignore the shortcomings inherent in this finishing material. Let's start with the fire hazard. Despite the fact that even cheap panels withstand temperatures up to 350 ÷ 400 ° C, open fire ignites them easily. Such plastic products burn with caustic, toxic smoke. Fatal for such products and mechanical damage.

Direct sunlight is contraindicated in materials of the low and medium price range - they "lead" them from ultraviolet radiation. And, of course, the psychological factor. Many believe that plastic gives residential premises a look of office. But this is a misconception based on ignorance of the market.

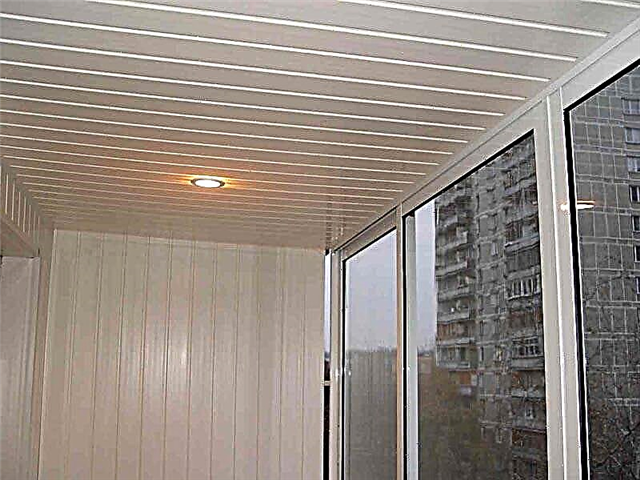

For a loggia, plastic trim is a good option

For a loggia, plastic trim is a good option

Modern finishing materials from plastic in appearance do not differ from natural wood or stone (depending on the design). Plastic can be distinguished only upon closer examination.

The choice of PVC panels: criteria and nuances

The first thing you should pay attention to is thickness and weight. At the same time, the thickness of the back does not matter, but the front is the key to strength. It should be understood that any crack on it is the penetration of moisture inside. Next, pay attention to the number of edges. The more of them, the higher the strength. In this case, the stiffeners should be perpendicular to the surfaces (front and rear). If this condition is not met, then they were stored in high piles and you can not even think about strength.

Accessories for connecting plastic panels during installation

Accessories for connecting plastic panels during installation

The connection of the panels (thorn-in-groove method) should be tight. It is better to check this directly with the purchase. Otherwise, abuse with the seller cannot be avoided. Another issue is the cost of the material. Do not think that a product of good quality can be purchased at a low price. Optimal here is the choice of the middle price category.

Important information! The main criterion for choosing panels should be the presence of installation experience. If it is absent, it is better to purchase more expensive material - it is easier to work with. As for cheap panels, often even a lot of experience does not save from moisture through seams and, as a result, the appearance of an unpleasant smell of mold in the room.

PVC panels: dimensions, release form

The length of wall or ceiling panels may vary. The most common parameters are 270, 300, 595 and 1200 cm. “Six” (595 cm) is most in demand. The width of the range of parameters is 10 ÷ 50 cm. If we talk about seamless products, then the popular size is 18 cm.

The thickness (as well as the number of ribs) depends on the purpose. The dimensions of the plastic panels for the ceiling in thickness are from 5 to 8 mm, the wall ones are slightly thicker.

Assembly scheme indicating the dimensions of one product and the decor below

Assembly scheme indicating the dimensions of one product and the decor below

The main types of PVC wall panels

Depending on the shape and size, the elements are divided into:

- tiled. They have the shape of a square with sides from 250 to 1000 mm. The small size of the elements complicates the implementation of installation work. They are attached to the base mainly by the frameless method. Thanks to the compact size they allow to realize various design projects,

- leafy. The most convenient option in terms of installation work. They allow using a single element to close a sufficiently large area. The size of the sides varies between 1220-2440 mm. Most often attached to the base by glue. The joints of the sheets are masked using moldings,

- rack and pinion. Rectangular elements having a length of up to 3700 mm and a width of up to 400 mm. Harmoniously fit into any room.

Drawing on PVC wall panels is applied in various ways. The image forms by:

- offset printing. The pattern is rolled onto a white base with a roller, then the decorative surface is varnished. The varnish layer is a good UV protection and extends the life of the product,

- thermal printing. The simplest and most affordable option, allowing you to apply absolutely any pattern.

Attention! Manufacturers offer PVC wall panels with a 3D pattern, which greatly expands the capabilities of designers.

Production material

For the manufacture of plastic panels, various materials are used. In its structure, it happens:

- layered. It is formed by the serial connection of decorative paper, kraft paper, overlay, which are pressed and impregnated with formaldehyde. Due to the layered structure, the material is more durable and reliable, able to withstand a significant load,

- foamed. It has a porous structure. The best option for rooms with high humidity. It has good thermal insulation characteristics. The surface of the material is rough,

- tough. It is made glossy or matte. Rigid plastic panels are often used to decorate door and window openings.

Specifications

PVC wall panels:

- allow operation in the temperature range from -50ºС to + 60ºС,

- keep properties under the influence of ultraviolet,

- have high hygroscopicity. Water is not absorbed into PVC wall panels,

- easy to install. You can do the finishing yourself without resorting to the help of professionals,

- easy to care. Various contaminants are easily washed off the formed surface,

- have sufficient strength when decorating walls inside the building,

- increase the heat and sound insulation characteristics of the room.

The special structure of PVC wall panels provides high technical characteristics.

The special structure of PVC wall panels provides high technical characteristics.Apartment and private house: photo examples

Often, PVC wall panels are used to decorate various rooms in an apartment or a private house. When choosing a material, the operating conditions and the general stylistic design of the room should be taken into account. We offer you to get acquainted with photos of completed projects, which you can use as an idea for subsequent implementation.

The size and pattern of the plastic elements determine the possible area of use.

The size and pattern of the plastic elements determine the possible area of use.

Living room and entrance hall

PVC wall panels allow you to originally design the interior in the living room. The availability of a wide range of colors and colors allows you to choose the best option for any interior. Solid pastel color products are quite popular. However, you can choose a model that simulates a certain natural material.

To design the hallway, you can choose bright and interesting panels. Actual abstract patterns and original flowers that will be combined with wooden furniture. To design a spacious corridor, it is worth choosing a material with a picture, shaded by a discreet pattern. Connoisseurs of elegance should pay attention to the panel with a wood pattern.

Bedroom and kids room

In the bedroom, PVC wall panels are of limited use. If it is decided to give preference to them, it is worth buying products with a printed pattern. You should not choose bright colors. The atmosphere created should have a comfortable rest.

It’s worth creating a comfortable atmosphere in the bedroom

It’s worth creating a comfortable atmosphere in the bedroom

In children's rooms, similar material is also rarely used. With their help, a gaming zone is formed mainly. Coloring can be very diverse.

Kitchen and bathroom

And here, PVC panels are used for wall decoration. Dirt and grease are easily removed from the surface of the material. This greatly facilitates the maintenance of decorative panels. A large assortment allows you to choose the right color for a particular interior. The choice is made taking into account the stylistic and color design of the kitchen.

Moisture-resistant material is ideal for decorating the walls of the bathroom. It can be used in showers and other rooms in which the walls are in direct contact with water. Appearance is selected individually, depending on the color of the plumbing and furniture.

Balcony, loggia and basement

For a balcony or a loggia it is worth getting the laminated PVC wall strips. They will be able to maintain their brightness for a long time under the scorching rays of the sun, will not collapse and deform at low temperature, and withstand mechanical stress. Drawing can be the most diverse.

The basement can be cozy

The basement can be cozy

Public premises

PVC wall panels are widely used in the design of public spaces. Presentable appearance, accessibility, ease of care makes them popular as a decoration material for walls of offices, trading floors, entertainment venues.

With the help of wall plastic panels, checkpoints are issued in various institutions

With the help of wall plastic panels, checkpoints are issued in various institutions

Offices and sales areas

The materials used to design the office premises should help create a working atmosphere. Bright colors should be avoided, making the choice in favor of muted tones. The size, depending on the generated pattern, can vary significantly.

Creating a business environment is easy

Creating a business environment is easy

For sales areas, you can choose PVC wall panels with a different pattern. Coloring can be correlated with corporate identity. Simulation of expensive materials will add to the presentability of the room.

You can save on the design of the trading floor without losing your presentability

You can save on the design of the trading floor without losing your presentability

Restaurants and bars

In restaurants and bars, PVC wall panels allow you to create a special cozy atmosphere, while maintaining a presentable appearance for a long time. They give the opportunity to decorate the interior in a certain theme.

PVC sheet panels help form a continuous coating

PVC sheet panels help form a continuous coating

Warehouses

PVC wall panels allow to refine the storage room. Good resistance to external factors makes it possible to use them for decoration of heated and unheated rooms.

With PVC wall panels, storage rooms look more modern

With PVC wall panels, storage rooms look more modern

Application options for PVC wall panels for building facades

Most often, polymer siding is used to decorate building facades. Special additives are introduced into the composition of the raw material, which improve operational characteristics and allow good resistance to external factors. Imitation of brickwork or stone decoration makes modular panels in demand in the design of the whole building or its individual parts.

Facade panels allow you to transform any building

Facade panels allow you to transform any building

Installation of PVC panels on the crate

The foundation is initially prepared. Old walls are dismantled from the walls. The existing defects are eliminated. A solution with fungicides is applied to prevent mold on the walls.

Installation work is carried out in the following sequence:

- We mark up. At a distance of 2 cm from the surface of the floor and ceiling, mark the points. We draw horizontal lines through them around the entire perimeter of the room. The accuracy of the spatial position is controlled using the building level and the masking thread. With a step of 30–40 cm, we draw vertical lines along which the crate will be mounted.

- Along the marking we prepare holes for fasteners in increments of 40–50 cm. We mount the crate from metal profiles or wooden battens. If wiring will take place under the panels, we provide places for its fixation. We make sure that it will not protrude above the formed surface.

- We lay, if planned, sound and heat insulation material. We fix it with glue or dowels.

- We fix the panels to the crate.

The wireframe method involves mounting on a crate

The wireframe method involves mounting on a crateAdhesive wall mount

The glue method allows you to abandon the installation of the frame. Plates are glued directly to the base. The latter should have perfect geometry. The presence of irregularities will reduce the adhesion strength of PVC wall panels to the base, as well as reduce the life of the formed coating.

For fixing, special glue and liquid nails are used. The adhesive should not contain solvents that can destroy PVC plastic panels.

Work with this type of installation is carried out in the following sequence:

- The base is cleaned, primed and dried.

- The adhesive composition is prepared and applied.

- A corner piece is fixed on the base, into the grooves of which PVC wall panels are inserted. Each element is pressed and held with force for 10-15 seconds so that it grasps with the base.

- Mounted decorative element.

- The interspace is treated with sealant or grout.

Attention! The frameless method can be used when facing rooms with a low level of humidity.

Share in the comments what application you found for PVC wall panels. Are you satisfied with the result?

PVC ceiling panels: main types

Ceiling finishing materials, like wall, are available in various versions. They can be:

- monophonic. This is the simplest version of unpainted products used in office premises,

- varnished. The disadvantage of the material is its susceptibility to the slightest scratches,

- with a printed drawing. The most popular panels for decorating loggias, bathrooms, bathrooms,

- laminated, with a structural pattern. The cost of such material is higher. Area of use - bathrooms, bathrooms, kitchen. Material is not used for decorating loggias - sunlight is destructive for it.

Photo printing on plastic - a complete sense of the reality of windows

Photo printing on plastic - a complete sense of the reality of windowsCommon sizes of PVC wall panels

For convenience, we combine the data on the wall finishing material in a table.

| View | Length cm | Width cm | Thickness mm |

| Rack | 90÷300 | 13.5÷30 | 6÷8 |

| Wall ordinary | 260, 270, 300 | 15÷50 | 8÷12 |

| Tiled | 30, 98 | 30, 98 | 2÷4 |

| Sheet | 98÷244 | 50÷122 | 3÷6 |

PVC sandwich panels for ceilings and walls: dimensions and prices

PVC sandwich panels are used to create slopes, as well as internal or external insulation of rooms, installation of partitions. Such material successfully replaces plasterboard partitions with a metal or wooden frame. The dimensional characteristics of them are as follows: 300 × 150 cm, 300 × 115 cm, 300 × 90 cm. Three products are available in thickness - 10, 24 and 32 mm. External plastic linings - 1 ÷ 2.4 mm.

The advantage of such a material is that after installation it does not require additional decoration. Corner seams and ends are closed with special overlays giving the partition or slope a finished aesthetic appearance.

The reality of the stone is not in doubt. But upon closer inspection, you realize that this is plastic

The reality of the stone is not in doubt. But upon closer inspection, you realize that this is plastic

The technology for joining plastic sandwich panels is similar to metal products of the same type. Installation is carried out with a thorn in groove lock, which eliminates the ingress of moisture. Another plus - plastic is not interesting to rodents and other pests. For example, if the block consists of polystyrene foam, and the lining is made of oriented chipboard (OSB), then this is a wonderful house for rats and mice - they gnaw holes in the foam. As a result, after 10 ÷ 15 years, the insulation does not remain inside. Plastic products are deprived of this problem.

Sheet panels are in demand for decoration of the kitchen and bathroom

Sheet panels are in demand for decoration of the kitchen and bathroom

At what price can I buy various types of PVC panels

Consider the cost of this finishing material as of January 2018:

| Colour | Application area | Size mm | Cost, rub / pc |

| Walls | 2700×250×8 | 170 | |

| Bathroom, toilet, kitchen | 2700×500×9 | 450 | |

| Bathroom, walls | 2700×250×8 | 220 | |

| Bathroom, toilet, kitchen | 2700×250×9 | 230 | |

| Room, walls | 2700×250×8 | 130 | |

| Slope sandwich | 1500×400×10 | 280 |

The range of colors of PVC panels on the Russian shelves of construction stores is quite wide

The range of colors of PVC panels on the Russian shelves of construction stores is quite wideRelated article:

Decorative panels for interior wall decoration. In this material we will consider the nuances of application in the interior and the advantages, materials and types, selection criteria, useful tips and recommendations of specialists.

Conclusion

PVC panels are without a doubt deserved popularity. Being a budget finish option, they allow you to carry out repairs so that the interior will have a rich look. Installation of such products is simple - even a novice master with no experience will cope with this work. In addition, not the least role is played by the ability to hide imperfections, uneven walls. This means that plastic panels will be produced for a long time, improving and improving.

We hope that the reader found in today's article information that interested him. If you have any questions during the reading process, our team will be happy to answer them in the comments below. Ask, communicate, share personal experience in the acquisition and installation of such finishing materials.

And finally, as always, a short video on today's topic:

The indisputable positive qualities of a sectional plastic lining include:

- Very easy installation.

- Lack of need of preliminary leveling of a surface.

- High speed finishes.

- Possibility of cleaning and washing the decorated surface.

For the installation of sectional lining on a wall or ceiling, a crate is assembled. It is made of metal profiles for drywall or wooden battens. The installation step of the rails is up to 60 cm. The thinner the lining, the thicker the lathing. Due to the possibility of using suspensions, the crate can be assembled exactly on a completely curved base. The quality of the wall or ceiling does not matter, since the final result of the cladding will always look good.

A positive point is the ease of attachment to the crate. The PVC panel is nailed to the wooden battens with stapler brackets or studs. It is attached to the profile with self-tapping screws.

Installation is very fast. To exclude viewing the end of the lining and its joints at the corners, specialized mounting elements are used. The PVC sheets themselves are inserted into the start profile. Corners are played by external and internal patch corners.

In modern repairs, the use of sectional plastic panels fades into the background. The fact is that the PVC panel has a lot of disadvantages. However, it can still be found on the ceilings, where the decor has minimal negative impact.

As for the smooth flat panels, they can be matte and glossy. Moreover, their decorative value depends on the technology of drawing the picture:

- Thermal transfer.

- Offset.

- Lamination

Thermal transfer the technology involves transferring the pattern to the surface of the panel by pressing a special film. Under heating, the image goes to the PVC panel. After that, the film is removed without a pattern, and transparent protection is glued on top and varnish is applied.

Offset the panels have a simple ink-printed image. The print head of an industrial printer prints directly on a large panel. This pattern looks bright, but it can be wiped as the operation.

Technology lamination It provides for simply sticking a patterned film onto the panel. During operation, it may peel off at the edges, but this is rare.

This is not to say that a separate technology is better than others. The durability and detail of the panel image depends only on the quality of materials and equipment.