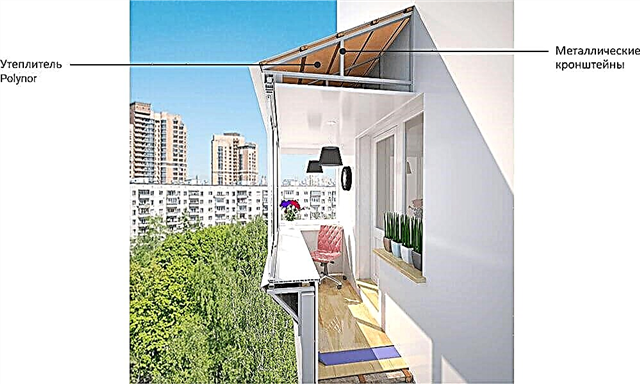

The Moscow Windows company took care of the residents of the last floors of old houses. People who got apartments with balconies without a roof. Today, solving this problem is easy. Moscow Windows will mount the roof and glaze your balcony quickly and not expensive.

Price: from 9 515 rubles per sq.m.

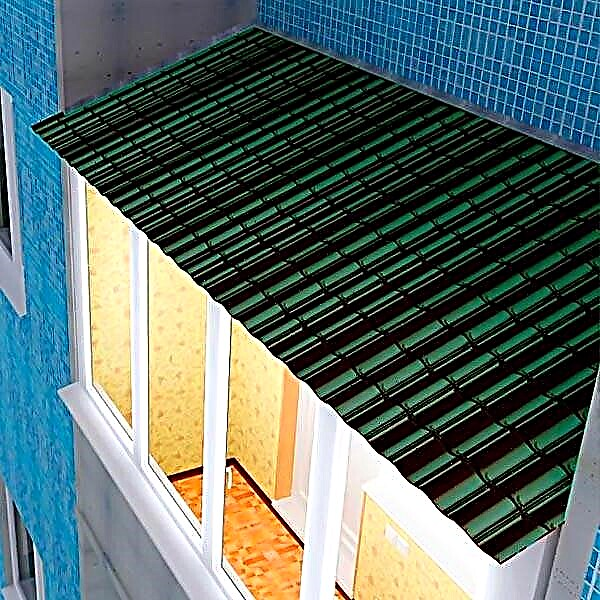

The roof is covered from above with S-21 corrugated board with a thickness of 0.45 mm in silver - RAL7004 color, which protects well from rain and wind. And inside it is insulated with professional material - sprayed POLYNOR insulation. It is responsible for maintaining a comfortable temperature and does not allow condensation to form.

POLYNOR sprayable insulation has several advantages.

- light enough weight and can be applied without consequences with a layer of any thickness to the surface of any material.

- the highest record thermal conductivity is observed in these materials, and amounts to about 0.020-0.028 W / mS.

- excellent sound insulation performance. This category of insulators successfully neutralizes even shock noises, providing silence in the room when working with construction tools

The design of the canopy can be straight, L-shaped or U-shaped (angle of rotation 90 °).

Complex constructions with indirect angles we do not perform.

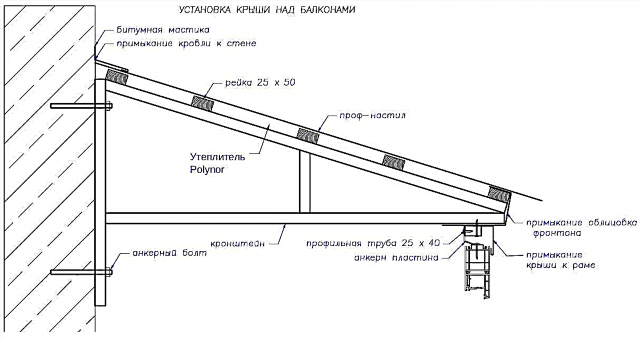

Below in Figure 1 are placed the technological drawings of the roof installation in the process of preparing the opening for the installation of glazing.

Fig. 1

Fig. 1

Glazing of balconies with a roof in Moscow

Quite often, owners of apartments on the top floors of houses turn to us with orders for glazing balconies with a roof. Our installers perform this work in one working day. The balcony on the top floor is the most unfavorable, because it does not have a roof over itself. Blown by all the winds and watered by all the rains. Precious heat is eroded from the apartment, respectively. We always approach such projects from a professional point of view and offer customers various options for arranging the roof as well as glazing balconies with a turnkey roof or with removal: cold or warm.

It is possible to manufacture structures on a metal frame, on a crate made of timber, or as it is called a lightweight version. Each design has a number of its characteristics and advantages. The differences lie in the appropriateness of using one or another structure for the roof and its price. Speaking about the glazing of balconies in Khrushchev with a roof, we would like to dwell on the most relevant aspects of this service, which most often concern consumers.

Is the base for the roof a metal structure or lathing? What material is covered - ondulin, iron? Will roof coverings make noise during rain and how to avoid it? And what is the price of glazing balconies with a roof?

Performing glazing of beams or loggias with a roof, our company makes the basis for two types of roofs. Metal construction in the form of brackets or using a lath made of wooden beams. You probably ask yourself a question, what will be more reliable? In this case, the word "reliable" incorrectly reflects the essence of the issue. It is better to say in which cases the first or second type of frame is used.

Metal brackets are used on the roof for glazing with plastic windows. PVC windows weigh quite a lot, therefore, especially strong fastenings are applied to them. It is worth emphasizing that the parapet and balcony should be strong, on which heavy PVC windows will be installed. The lath made of timber is used for the roof in conjunction with aluminum frames. Aluminum balcony glazing is several times lighter than plastic windows and twice as strong as them. It is enough to make a transverse crate, which perfectly copes with the task of reliable fastening. On balconies with such a lightweight design, the stove experiences the least load. What is an additional plus to a lower price. However, at the request of the customer, it is possible to install aluminum frames using brackets. Simply, such work will cost more due to the presence of additional costs in the estimate.

A balcony without a roof needs a special glazing scheme. The frame block is not made entirely of four sliding sashes, as is the case with ordinary glazing, but in two sections. For example, glazing for a three-meter-long roof is made of two sections. In each one and a half meter section there are two sliding sashes, and there are four in total. An I-beam connects two bivalve sections in the center in a single unit and adds strength to the entire structure. What contributes to the stability of the product even with strong gusts of wind. Even a hurricane is fearless to our roofs. This is a common practice in our region, tested by time and weather conditions. In addition, additional rigidity will provide stability when glazing a balcony with a roof and stem.

GLAZING OF BALCONIES IN KHRUSHCHEVKA WITH A ROOF IN MOSCOW - WE CHOOSE MATERIAL FOR ROOF ROOF

Ondulin is a material made from cellulose with the addition of bitumen impurities, dyes. Simply put, this is pressed cardboard impregnated with a special water-repellent composition. It has a wavy shape similar to the roof gland. If we compare its service life with iron, then it is very small, manufacturers declare a 15 year warranty. When heated, it emits the smell of bitumen. On the Internet there are photos with curved roofs. In the comments to them it is said that this happened because the glazing of the balconies with the roof was done without a metal structure. In fact, in this case they used ondulin, which could not withstand the weight of snow and ice. In such cases, it is obvious that ondulin was used for other purposes and the proper crate was not made. Considering how our wipers clean the roofs, sometimes throwing huge icicles directly onto the balconies, it is worth thinking carefully about using this type of coating.

Ondulin is a material made from cellulose with the addition of bitumen impurities, dyes. Simply put, this is pressed cardboard impregnated with a special water-repellent composition. It has a wavy shape similar to the roof gland. If we compare its service life with iron, then it is very small, manufacturers declare a 15 year warranty. When heated, it emits the smell of bitumen. On the Internet there are photos with curved roofs. In the comments to them it is said that this happened because the glazing of the balconies with the roof was done without a metal structure. In fact, in this case they used ondulin, which could not withstand the weight of snow and ice. In such cases, it is obvious that ondulin was used for other purposes and the proper crate was not made. Considering how our wipers clean the roofs, sometimes throwing huge icicles directly onto the balconies, it is worth thinking carefully about using this type of coating.

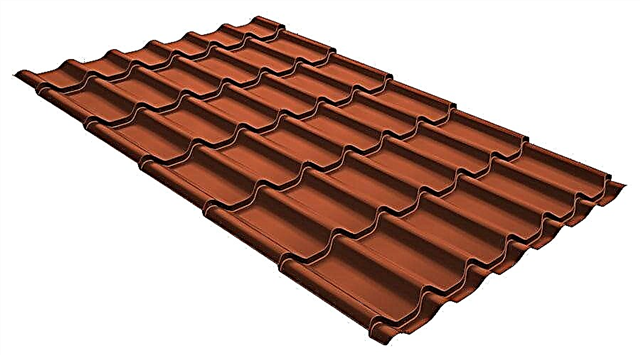

The popularity of roofing iron is explained by its practicality and long service life, which is more than 30 years. The corrugated sheet has a low specific weight, which can significantly reduce the load on the balconies. It has the shape of a trapezoid, which plays the role of stiffening ribs. Due to this, the sheet has an increased level of strength. Galvanized coating is not susceptible to corrosion and rust. Of the possible disadvantages, it is worth noting the average noise level during rain. This problem is solved due to the rigidity of the sheet fastening around the entire perimeter of the roof, which dampens vibration and sound. Note that mostly balconies in depth are approximately 70-80 centimeters, there is nothing much to make noise on such a narrow area. Loggias without roofs can be up to 120 centimeters deep, but we have a proposal for this situation. For customers who are particularly susceptible to sounds, we suggest glazing the balcony with the roof, as well as pasting the roof from the inside with a soft foam. He dampens the sounds and insulates the roof. And the ceiling decoration will hide under itself all ugly building elements and will become an additional barrier to sound and cold. It is this type of decoration that we strongly recommend to perform on the balcony with a roof for its aesthetic appearance.

The popularity of roofing iron is explained by its practicality and long service life, which is more than 30 years. The corrugated sheet has a low specific weight, which can significantly reduce the load on the balconies. It has the shape of a trapezoid, which plays the role of stiffening ribs. Due to this, the sheet has an increased level of strength. Galvanized coating is not susceptible to corrosion and rust. Of the possible disadvantages, it is worth noting the average noise level during rain. This problem is solved due to the rigidity of the sheet fastening around the entire perimeter of the roof, which dampens vibration and sound. Note that mostly balconies in depth are approximately 70-80 centimeters, there is nothing much to make noise on such a narrow area. Loggias without roofs can be up to 120 centimeters deep, but we have a proposal for this situation. For customers who are particularly susceptible to sounds, we suggest glazing the balcony with the roof, as well as pasting the roof from the inside with a soft foam. He dampens the sounds and insulates the roof. And the ceiling decoration will hide under itself all ugly building elements and will become an additional barrier to sound and cold. It is this type of decoration that we strongly recommend to perform on the balcony with a roof for its aesthetic appearance.

ADDITIONAL DEVELOPMENT WORKS

As a heat and noise insulation of the roof, we propose to glue it with foil foamed foam. Such an additional service is necessarily carried out with warm glazing of balconies with a roof with plastic windows. The porous pad retains more heat and reduces noise to a maximum minimum. Of course, the cost of glazing balconies installing roofs in this embodiment will cost a little more, but in this case you will not be bothered by the monotonous noise of rain.

As a heat and noise insulation of the roof, we propose to glue it with foil foamed foam. Such an additional service is necessarily carried out with warm glazing of balconies with a roof with plastic windows. The porous pad retains more heat and reduces noise to a maximum minimum. Of course, the cost of glazing balconies installing roofs in this embodiment will cost a little more, but in this case you will not be bothered by the monotonous noise of rain.

Also, we propose to install a tumble dryer for the improvement of linen like "liana". This device has proven itself with customers, but requires preliminary preparation for installation. The fact is that the clothes dryer is attached to the top plate of the balcony, but there is no such plate on the balcony without a roof, so glazing of balconies with a roof is necessary. And this means it is necessary to foresee the installation of fixtures in advance, with which the drying will be securely fixed. Now the hostess can comfortably dry the clothes previously squeezed in the washing machine.

In addition to glazing a balcony with a roof, we strongly recommend that customers order a ceiling decoration service. It will hide under itself all the ugly building elements such as fasteners, galvanized corrugated sheets, etc. Our proposal is that you order a ceiling finish at a standard price, which currently costs five thousand rubles. And we glue the roof with foil penofol for free. Or with a more expensive order, we will set up a clothes dryer as a gift. If you need glazing of loggias or glazing of balconies with a roof in Moscow or in the Moscow region - contact our company! Professional engineers are enthusiastic about each project for glazing a loggia or a balcony with a roof, and the prices for all the services of our company are maintained at an optimal and affordable level.

Types of balcony glazing

When choosing a glazing options are possible:

- Cold - provides protection from rain, wind and dust, but does not provide protection from extreme cold and heat. Apply when the balcony is used only in the warm season. To do this, use inexpensive aluminum glazing or lightweight plastic frames with single-chamber double-glazed windows. This option is only possible if the base plate has restrictions on the permissible load.

- Warm - provides sufficient thermal insulation so that it is comfortable to be on the loggia at any time of the year. Apply PVC profiles and multi-chamber double-glazed windows. “Warm” glazing is carried out in parallel with the insulation of the loggia (covering the floor, walls and ceiling with insulation). The design has a significant weight, so it is not always used.

Profiles differ in the way the shutters are opened: swing or sliding. You can close the glass space from the parapet to the roof or completely, starting from the floor (panoramic balcony). The choice of how to glaze a balcony with a roof depends on the condition of the stove, the purpose of the room and the budget.

Wooden frames for the roof

Wooden structures are quite durable if the beams are made of quality wood. The light weight and ease of installation speaks in their favor. Wood does not conduct heat well, which is especially important for a “warm” balcony. The advantages include the low cost of the material, as well as environmental friendliness.

Important! Parts of the structure made of wood must be treated with special impregnations. This will protect them from premature destruction under the influence of low and high temperatures, high humidity.

With all the advantages, a wooden frame has disadvantages:

- Short service life in comparison with a metal analog. Wooden elements are destroyed by weather conditions. Protective coating treatments are not always effective.

- Fragility at attachment points. The frame is fixed with screws. Over time, under mechanical action (strong wind), these places become loose and cold bridges form.

- Beams can have different densities, which over time will lead to skew design.

Varieties of metal frames for the roof

For higher reliability of the roof balcony, it is recommended to build a metal frame. He has a heavier weight and at a price it will cost more. The metal has good thermal conductivity. For a well-maintained balcony on the top floor, more thorough insulation of such roofs is required. These disadvantages are offset by durability and a long service life.

Metal supports have several options:

- fixation on farms (corners),

- elements from the profiled pipe are fastened by welding,

- the frame is made using screw fasteners.

Useful! To extend the period of operation of the metal frame, its parts are coated with a paint with anti-corrosion effect.

Supports made of metal will last several decades if the installation is carried out in accordance with the standards. Often use a combination of metal and wood parts.

Types of balcony roofs

The roof structures differ not only in the material of the frame, but also in the way of fastening. It is necessary to think in advance how the canopy will be fixed. Making changes after completion of work will entail additional costs and is not always possible. When choosing a mounting method, the following factors should be considered:

- roof size

- will the balcony be glazed

- condition of bearing ceilings.

Often the need for a canopy arises when glazing a balcony without a roof. In the absence of a top plate, the installation of window frames is impossible and impractical. You can glaze both before the installation of the roof and after. But the type of roof will be different. The canopies of the independent mounting method are installed before glazing, and the dependent one after.

Independent roof

The design is attached to the external wall of the house and does not rest on window frames and a base plate. Although there are options when the structure is reinforced with additional beams with support on the slab.

The main load of the frame lies on the corners. For greater strength, angles are installed at an angle with wall mounts. This fastening method is suitable if no further glazing is planned or the bearing capacity of the floors is weak.

An independent design should be chosen for the following reasons:

- Provides rain protection.

- Can be installed on a small balcony.

- Does not load the base plate.

- Relatively simple installation, it is possible to do it yourself.

Sometimes these advantages are not enough to stop the choice on this type of roof. The disadvantages should be taken into account:

- Cannot be installed on wide loggias.

- In strong winds, the installation may not withstand.

- If the balcony is already glazed, then such a roof will not work.

- For roofing, only light material should be used.

- The design does not withstand heavy snow cover and can collapse from the impact of icicles.

If you plan to “warm” glazing with the installation of a roof on the top floor, then this design will not work. An independent frame will not withstand the weight of insulation materials, and without them a warm balcony will not work.

Dependent roof

With this type, the frame is attached to the wall of the building, and to the frame of the balcony. Installation is made after the installation of window frames.

The advantages of this type of mount:

- There are no restrictions on the size of the loggia or balcony.

- You can use any materials for roofing and insulation.

- It does not deform due to the weight of snow and gusts of wind.

- Creates reliable protection against external conditions.

The disadvantages include:

- More complicated installation, special equipment is required. It is better to contact specialized companies.

- It can only be installed on reliable balcony foundations. It is necessary to know in advance whether the slab will support the weight of the roof and glazing.

- This design will cost more.

Roofing materials for glazing a balcony with a roof

The roof covering is made of the following materials:

- Decking. It has low weight and low cost. It is characterized by reliability and a long service life. Suitable for "cold" glazing.

- Metal tile. It has the characteristics of corrugated board, but has a more decorative appearance. Thanks to an additional top layer it provides better protection and longer service life.

- Polycarbonate This option is suitable for those who dream of a glass roof on the balcony. It is lightweight and durable. It does not provide sufficient noise and heat insulation, and also does not protect from sunlight.

- Ondulin, or Euroslate. It has low weight, good tightness and durability. Suitable for "warm" glazing.

When glazing a balcony without a top plate, many factors must be taken into account: assess the condition of the balcony base, determine the method of fixing and covering the roof.

For high-altitude work, special equipment will be required. It is not recommended to do this on your own. It is better to study the reviews and contact a reputable company with extensive experience in these works. High-quality glazing and roof installation makes it possible to forget about the repair on the balcony for 20-25 years.

Types of sashes: swing, sliding and rotary

Believe me, choosing the type of glazing is not only a matter of comfort and aesthetics. If anyone is faced with the problem of icing the doors, these are residents of the last floors. The shutter gets stuck, someone pulls it harder - and the whole structure is broken. Therefore, take the choice of glazing seriously. Most often, three main types of sashes for a balcony are used: swing, sliding or pivoting, popularly called pendulum.

Swing sashes are good in that they have the best noise protection, tightness and structural rigidity. They always open inwards, which is safe and convenient to care for them. The only thing is that the balcony space in this case, of course, is limited, and there will no longer be any flowerpots or statuettes on the windowsill.

Because of this, deaf or sliding sections are often placed. Sliding in appearance look like compartment doors and are good because they allow you to use the entire window sill and floors. But they are even more susceptible to freezing in frost than oar, and this is better taken into account. Another drawback of sliding systems is that they do not have a solid vestibule, i.e. necessary tightness, and especially with aluminum structures.

Even at the glazing stage, think about whether you want the side parts of the balcony to open - for those it is better to put a rotary shutter. By the way, today it’s fashionable to install a sliding glass roof on the balcony, in which the panels come in motion from an electric motor. In this case, the glazing is even made deaf, i.e. without opening flaps, and all ventilation is due to the opening roof.

In terms of fire safety, this is considered a violation, but sometimes there is no other way out if a mentally ill person lives in the apartment on the top floor, who can open the windows on the balcony and fall out. And then you have to go for such measures. Simple, know that such a glazing option exists, and, of course, is possible to be performed only on the top floor, where there is no other balcony above the balcony.

Selection of glazing profiles: PVC, aluminum or wood?

First of all, let's look at the types of glazing, which are divided into two main groups: cold and warm.

First of all, let's look at the types of glazing, which are divided into two main groups: cold and warm.

Warm glazing is one that protects against street cold, and, in scientific terms, has the necessary resistance to heat transfer. This is usually a double-glazed frame or twin frames. Warm glazing should always be supplemented by insulation of the floor and ceiling, otherwise it will not make any sense.

But cold glazing is needed in order to simply protect the space of the balcony from noise, dusty air and precipitation. Of course, its presence alone also warms the balcony in its own way. In any case, high-quality glazing of the balcony involves the use of such materials so that subsequently the wind does not cause the frame to skew, rattle or break.

Of course, the material for manufacturing the profile is everyone’s personal choice, and it cannot be said that any of the systems is universal. Although experienced builders often say that the PVC structure is designed just for insulation, for thermal insulation of window openings, but it has considerable weight, and therefore it is specifically for the top floor that the aluminum system is recommended.

Although a good measurer will not insist on any profile, everyone really has its own advantages.

PVC: achieving the right microclimate

PVC glazing has such advantages as sound insulation, safety and high strength. Install PVC structures in this way:

- Step 1. First reinforce the parapet, if necessary, or make new brickwork. After all, the PVC construction has considerable weight, and the stability of the parapet on the top floor often leaves much to be desired.

- Step 2. Install the frames and the upper visor, and mount the tide 100-150 mm. The window sill should be done with at least 150 mm so as not to interfere with the interior decoration.

- Step 3. After that, a stripper is installed outside the perimeter of the balcony. As you can see from the step-by-step master class, the easiest way to connect the roof of the balcony with PVC glazing frames is with mounting foam.

Aluminum: versatile

Such popular aluminum sliding systems are good for their ease of installation, price and ease of construction. Today they are only gaining popularity and delight owners of balconies with durability, strength, environmental friendliness and lightness.

Such popular aluminum sliding systems are good for their ease of installation, price and ease of construction. Today they are only gaining popularity and delight owners of balconies with durability, strength, environmental friendliness and lightness.

It is aluminum structures that are produced in the widest color, which cannot but please the design soul of our compatriots. In fact, such windows can be painted in any color according to the RAL catalog, or glued with a protective film under antique bronze, gold or silver.

But in winter, ice often forms on the balconies of the upper floors in aluminum skids. In addition, this design is not the safest, and usually does not protect well from the cold. There is also an opinion that aluminum balconies are bad because they "flow".

Although in fact, specifically in working with metal, you just need to take into account the laws of physics and build at least a simple type of drainage system - then the balcony will turn out to be dry and warm. Due to the light weight of the aluminum system, it is especially convenient to do it “on the floor”, attaching directly to the parapet on metal racks.

There is another important point that is often forgotten when speaking about the balconies of the last floors: they are also not protected from breaking, like the balconies of the first floors. It is usually not difficult for criminals to get down from the roof canopy to the balcony.

So, the aluminum structure in terms of protection against hacking is the weakest. It is opened quite easily. Therefore, we advise you to install immediately on aluminum glazing, and on PVC - grille. After all, do not forget that the runs were originally designed for fire safety and the possibility of evacuation.

The fact that aluminum profiles are lightweight gives an advantage in the implementation of complex projects. For example, when the balcony is expanded along the wall or a rather complicated roof is made, which needs a reliable, but not heavy support.

Wood: for special comfort and closeness to nature Wooden glazing is made of pine or spruce frames of a small section. Usually there is one glass with a thickness of 4 mm, and the wings are made oar. With additional interior decoration of the balcony, such glazing helps to increase the temperature by 70 ° C in comparison with the street, and reduce noise by 7-10 decibels.

Of the advantages, we note that the wings themselves are small and elegant due to the high rigidity of the frames. But periodically, these wooden frames need to be tinted to protect against rot.

Here is a detailed instruction on how to install wooden glazing on the top floor:

- Step 1. Attach welded brackets to the parapet in order to make the glazing slightly.

- Step 2. On them, fix the wide shelf and level it. Now fix a wooden shelf on it, and fix it to the wall of the house with three facade dowels.

- Step 3. Now expose the frames, starting from a blank wall, one after another, while first screwing them to the windowsill, and then only connect them together. Apply sealant to all seams and joints.

- Step 4. When finished with the side frame, proceed with the installation of the roof. To do this, you will need to attach a structure of a 50x50 mm bar to the wall of the house, which should be located slightly above the abutment line.

- Step 5. Now assemble the roof structure and put it under the visor. Align on the short side of the balcony and press firmly against the wall.

- Step 6. Lay the roofing sheets with an overlap on each other. Lock them and fill the seams.

- Step 7. Put the tides around the perimeter of the glazing, fill the seam between the roof and the wall of the house. After that, glaze the frames, seal them up and press with glazing beads. Glazing is ready.

Wooden frames serve less in time than PVC or aluminum, but in their own way are popular among environmental lovers in everything. Frameless glazing: a tribute to French fashion And about the latest. On the top floor, as you know, the city is best seen, and therefore frameless glazing is becoming increasingly popular.

At the same time, keep in mind that frameless glazing of the balcony of the last floor has some disadvantages. After all, here the glass does not travel along the lower rails, but only along the upper, and at the same time they weigh a lot. In order to securely fix them, you will have to transfer the entire load to the roof of the balcony.

Therefore, when it comes to the top floor, remember that there is no strong slab of another balcony on top. At the same time, if you still light up to install frameless glazing on your balcony, many companies will take it and will boast that they "break stereotypes." But what this will turn into in the future - they will no longer concern them.

And finally, keep in mind that frameless glazing, in essence, is still more decorative. It does not protect too well from rain, cold or dust, since there are many gaps in this design. For the balcony of the last floor - this is not the best option, but such a balcony, of course, is well ventilated, there is no condensation inside, the wings do not freeze, and the glass does not freeze. Therefore, if you are quite comfortable with such a summer option, why not?

We select the glazing material: a filter for the sun

It is clear that on the top floor of the sun the most. After all, such balconies are not covered neither by trees, nor by the construction of the courtyard, nor even by neighboring houses. At first it’s good: it’s so sunny on the balcony that you don’t need to go outside. But, if you decide to equip your personal office or a recreation area there, the blinding sun rays can be annoying, not to mention the fact that in the summer they will arrange a real sauna on the balcony.

It is clear that on the top floor of the sun the most. After all, such balconies are not covered neither by trees, nor by the construction of the courtyard, nor even by neighboring houses. At first it’s good: it’s so sunny on the balcony that you don’t need to go outside. But, if you decide to equip your personal office or a recreation area there, the blinding sun rays can be annoying, not to mention the fact that in the summer they will arrange a real sauna on the balcony.

Therefore, fashionable tinting completely solves this problem, the only thing is that we advise you to give preference to transparent glass, and only then, from the side of the room, already glue the tint film, which will additionally cover your balcony from prying neighbors (or thieving) eyes.

In addition, today they release films that effectively imitate embossing - very beautiful and practical. But there are also disadvantages here. For example, in cloudy weather, the light will already be lacking, and the film itself will easily be scratched, and if you decide to get rid of it, you will suffer. By the way, glass, which is supplied by modern companies for balconies, is protected by a special protective film even in the factory.

It not only reduces the transmittance of ultraviolet rays to 75%, but also allows you to reduce the transparency of the balcony from the side of the street so that it is difficult to consider something on it. In addition, glass is far from the only glazing option.

But if you want to glaze the balcony with polycarbonate, which is quite possible and universally practiced, choose transparent monolithic or honeycomb sheets. In any case, here the console guides will be visible, they are usually made from a profile pipe and painted in color (usually white), then the general view of the balcony is quite tolerable.

Cellular polycarbonate for a balcony is good in that it retains heat, harmful UV rays and gently scatters light. These flaps can be done all or only side, at your discretion.

What to do with a weak fence?

Now let's move on to the issue of glazing complexity. The fact is that the balconies of the last floors in our country have one unpleasant feature, and in almost all cities, these are weak metal supports. It’s quite difficult to install plastic structures on them, and therefore it is often necessary to strengthen the entire structure or completely digest the balcony enclosure. This is another reason to understand the intricacies of glazing, so that later the balcony does not rest on parole.

But, since you have to redo the fence of the balcony, do not miss the opportunity to make it wider, with the so-called extension. Especially if you are brewing a new metal frame - then it makes sense to you to immediately make it more powerful. After all, it happens that there is no parapet, or the old one had to be demolished.

The metal version is good in that it is easy to install, even PVC structures stand firmly on it, and it is easily finished with siding. The only thing you have to tinker with is warming. But, unlike him, the laying of a parapet of blocks or bricks protects the balcony well from the cold, and, at the same time, it is heavier, more expensive and difficult to finish from the outside.

And finally, another great option is to install glazing as a solid structure, we already mentioned this option above. Firstly, it looks much more aesthetic, because it is lighter and does not need to be finished at all. In addition, the windows in this design are much larger in area (there are no restrictions), wider and higher than with a conventional parapet.

You can also choose the color of the glazing (not necessarily white). Such a balcony really looks incredible! Among the minuses, we note only a rather complicated installation, the duration of the work and the need for professional measurement. Well, the cost of dismantling the old fence.

So, here's how to make a complete glazing of a balcony step by step as a solid structure:

- Step 1. We remove the old metal or brick structure.

- Step 2. Install the mount on the balcony, where the front part will consist of four frames: upper open and lower deaf, not open.

- Step 3. Next, along the perimeter of the balcony, you need to install expanders and extensions in 45 mm thick, under the system you have chosen. You need them in order to leave a little space for insulation or ceiling decoration.

- Step 4. Now install both types of frames, and, if desired, install a window sill at their junction, if you need one. It is only important that the height of the lower frames, which serve as a replacement for the parapet, be at least 1 meter and not more than 125 cm.

- Step 5. Place metal strips on the outside, 60-70 mm each.

- Step 6. Finally, cover all the cracks with mounting foam. And the whole construction is ready!

It remains only to make sure that the balcony with the roof is reliably protected not only from slanting rain, but also from extreme weather conditions. Protecting the roof balcony from leaks When the glazing is completed, it is important to take care of its long service life. Remember that the balcony of the top floor is always the first to take a storm. And therefore, in the process of glazing, the joints between the frames are immediately treated with special foam, and then with sealant.

It is also important to avoid icing. Usually it occurs on either a too cold balcony or too well insulated. Here ventilation will help you, forced or natural, through the cracks. After all, sealing and dense insulation in a sense worsens ventilation.

And water vapor easily penetrates from the living room onto the balcony, condenses and settles in the form of drops, after which it flows onto the floor. That is why a balcony with a roof, regardless of its type of glazing, should have a drainage system. After all, we are talking about the top floor, which means that over this balcony there are no others who would take the bulk of the rainfall upon themselves. And therefore, for this purpose, think over the external and internal gutters. And then, with a competent approach, the new balcony will serve you for a long time!

How to install a roof over a balcony?

The benefit of the roof, or at least a visor above the balcony, is undeniable.Even light rain will demonstrate the validity of this statement. The need to install a full roof arises if there is no balcony above the floor, for example, when the apartment is located on the top floor. In other cases, you can get by with a small visor.

The benefit of the roof, or at least a visor above the balcony, is undeniable.Even light rain will demonstrate the validity of this statement. The need to install a full roof arises if there is no balcony above the floor, for example, when the apartment is located on the top floor. In other cases, you can get by with a small visor.

Before installing the roof on the balcony, you need to determine the design of the frame and its fastening. The frame may be metal or wood. For obvious reasons, preference is usually given to metal structures, but wooden bars are still used as a lathing under the roof.

The most popular material for the roof frame is a metal corner. It has a small price, parts from it are easy to dock when assembling structures, they are conveniently fastened with both welding and bolts. Assembly on bolts is more labor-consuming, but it is used in cases when welding is unavailable or unacceptable for any reason.

The roof on the balcony is installed in one of two main ways: with the frame fastened to the base wall without support on the balcony slab or with support on the window structure.

The first installation option places higher demands on the rigidity of the frame and the reliability of the fasteners. To reduce the load on the gap in the upper row of fasteners, the fixation points must be spaced as high as possible. A self-supporting roof is usually used with lightweight aluminum glazing or when there is no glazing at all. It allows you to avoid additional load on the balcony slab.

The second option is simpler constructively. It is used for glazing balconies with a roof, in general, this design is more rigid, it is a system where each element increases the reliability of all the others. It is usually used with full "warm" glazing, in which the additional load from the roof is small.

It’s easier to build a roof over the loggia than a roof over the balcony, since the frame is attached to the side walls.

How to cover the roof over the balcony?

When mounting the roof on the balcony, for the roof, you should choose lightweight materials that are convenient for installation. It:

- corrugated board

- galvanized sheet

- metal tile

- cardboard bitumen slate (ondulin),

- cellular or corrugated polycarbonate.

Of all these materials, only tin requires a solid foundation; for others, a crate of three or four bars is mounted. Cellular polycarbonate with a correctly designed and carefully made frame does not need a crate at all. But not every company will undertake such work.

How to close up the cracks?

To make the balcony truly weatherproof, it is necessary to carefully repair all joints: roofs with a wall, glazing of a balcony with a roof, frame with side walls, etc. Cracks are constant drafts, dust and snow falling inside, the inability to retain heat.

Slots through which water can flow in are sealed with silicone or bitumen sealant, glued with butyl rubber tape. Where there is no constant exposure to water, you can use acrylic sealants.

Roofing material

The following materials are most often used as roofing materials:

- polycarbonate

- galvanized iron,

- ondulin.

Polycarbonate is used to make fashionable transparent roofs only according to an independent system. This expensive material is good for everyone except, perhaps, the price - not everyone can afford it.

Moreover, the most significant drawback of iron - its noise - can be easily eliminated. To do this, apply a three-millimeter layer of self-adhesive sealant. It has soundproofing qualities and several times reduces the sound volume from rain or wind.

Finally, a coating of ondulin. It is, in fact, a reinforced roofing material. This soft roof is easy to install and has the properties of vapor and sound insulation. But at the same time, the rough surface prevents the sliding of snow, and the ondulin coating itself burns out in the sun, is unstable to shock, and is relatively expensive.

Wood or metal? Choosing the material for the supporting structure

Regardless of whether you choose cold or warm glazing of balconies, the installation of the roof must be correctly calculated and properly performed. And first of all, it is necessary to decide which material to use for the manufacture of the supporting structure. What should be preferred - wood or metal?

WHAT A ROOF BALCONY IS NEEDED FOR?

A well-made roof must meet a number of requirements:

- to be light and, at the same time, durable,

- have such an angle so that precipitation does not accumulate on it,

- withstand wind loads

- provide thermal insulation of the room.

GLAZING OPTIONS

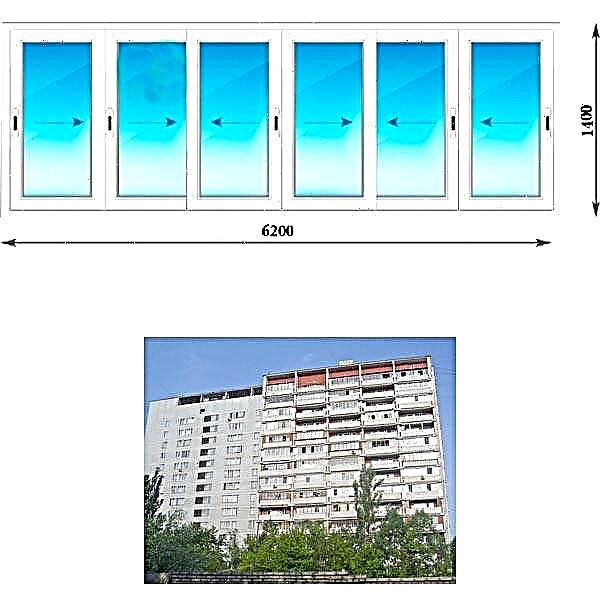

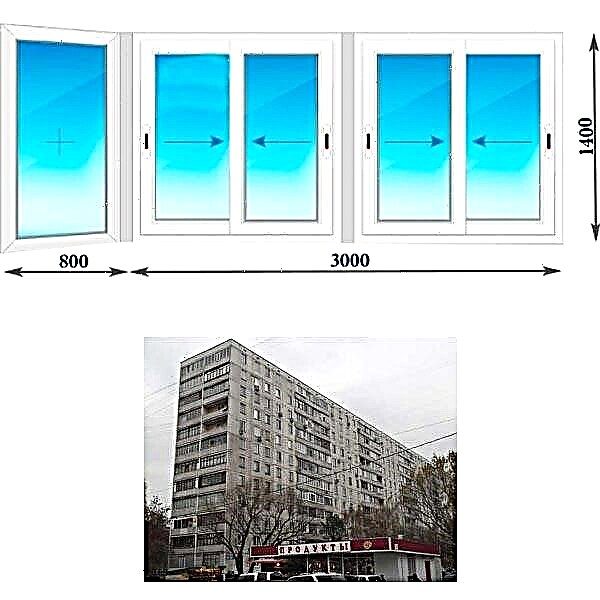

Glazing of a balcony in Khrushchev with a roof

- Aluminum

35.000p - PVC

41.000p

Glazing of the 6th loggia with a roof

- Aluminum

39.000p - PVC

45.000p

Glazing of the 3rd loggia with a roof

- Aluminum

27.000p - PVC

34.000p

Panoramic glazing with a roof

- Aluminum

49.000p - PVC

54.000p

EXAMPLES OF OUR WORKS

ROOF GLAZING AND

FINISH

Extendable aluminum profile Provedal.

Price with installation

38.000 ₽.

TYPES OF BALCONY GLAZING

When the customer has decided what the room will be used for, you can choose a profile, a double-glazed window and a method of roof insulation. In Moscow, for the glazing of balconies with a roof at an affordable price, PVC and aluminum structures are used.

When it comes to the modernization of non-residential premises, aluminum profiles are used that are lightweight and easy to install. PVC frames allow you to organize more expensive, warm glazing. Such a balcony can be used throughout the year, if you provide for sealing and arrange additional heating.

Work execution order:

- Strengthening the parapet.

- Removal of glazing (if necessary).

- Installation of a plastic frame.

- The construction of the metal frame.

- Installation of the roof.

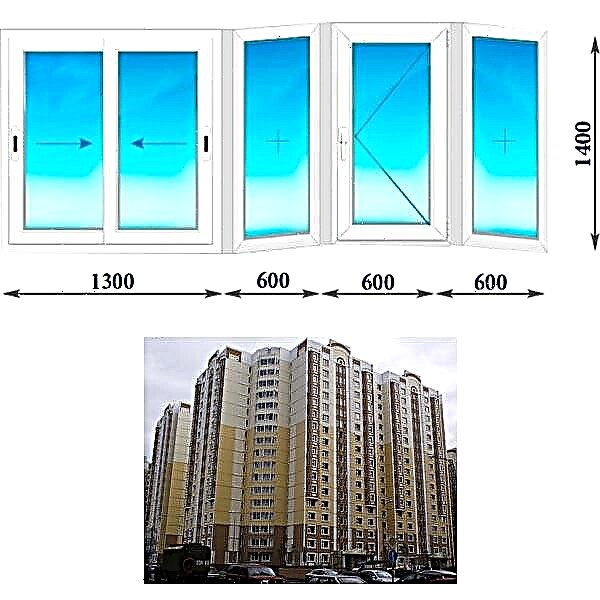

House Series I-515

- Cold

18.500p - Warm

26.800p

- Cold

17.000p - Warm

25.000p

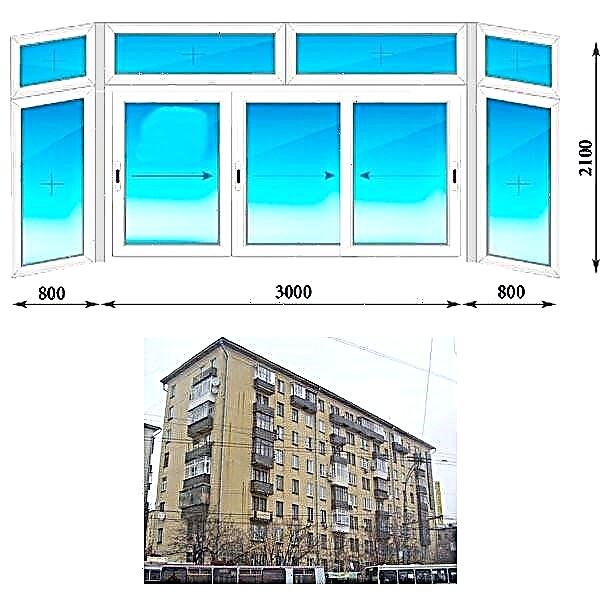

House Series II-01

- Cold

25.500p - Warm

30.200p

- Cold

23.000 rub - Warm

33.300

- Cold

26.400p - Warm

37.000p

- Cold

18.000p - Warm

27.800p

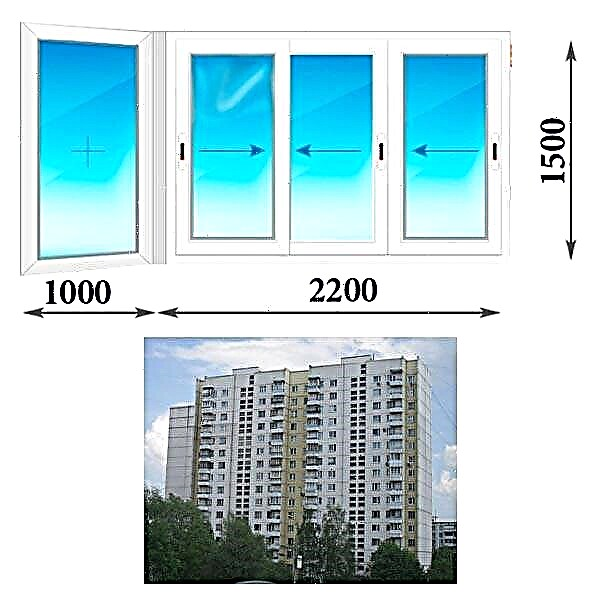

House series P44-T

- Cold

23.800p - Warm

34.200p

House Series II-04

- Cold

38.700r - Warm

48.200

- Cold

27.800p - Warm

36.700p

House series P-3,

U-shaped balcony

- Cold

20.500p - Warm

29.600p

House series P-3,

corner loggia

- Cold

18.300p - Warm

27.800p

House series P-3,

6 meter loggia

- Cold

26.200 rub - Warm

42.000

House Series

1605

- Cold

23.000p - Warm

30.700p

House series PD-4,

large loggia

- Cold

36.200p - Warm

48.800p

House Series

I-700A

- Cold

25.000p - Warm

39.000p

House series P3-M,

corner loggia

- Cold

19.500r - Warm

30.200

House Series

I-1605

- Cold

18.300p - Warm

27.200p

House Series

P-55M

- Cold

22.300p - Warm

32.800p

House Series

PD-4 small loggia

- Cold

25.600p - Warm

32.700p

- Cold

30.300r - Warm

47.000

House Series

1MG-600

- Cold

23.000p - Warm

32.000p

- Cold

18.500p - Warm

28.000p

House Series

KOPE

- Cold

17.900p - Warm

23.800p

House Series

1-515

- Cold

25.600r - Warm

35.700

EXAMPLE OF COLD GLAZING ROOF BALCONY

TOTAL COST:

Glazing Provedal - 24.000 ₽.

Installation of roofing from corrugated board - 5.800 ₽.

Ceiling Finish - 3.700 ₽.

TOTAL: 33.500 ₽.

The calculation includes the Provedal design, visors, tides and consumables.

TYPES OF BALCONY ROOF

- dependent and independent,

- frame and frameless,

- warm and cold

- transparent and not.

Depending on the method of fastening, the roof can be an independent element and can be mounted on the wall or be an integral part of the glazing. The roof frame is made of a profile pipe, according to the type of screw connection or “on trusses”.

As a roofing material, metal profiled sheet is most often used. It is possible to lay light and airtight bituminous tiles, however, it has high combustibility. The metal tile protects well from the effects of the external environment, but differs in low sound insulation. A transparent, lightweight roof is made from cellular and monolithic polycarbonate.

In the Osteklim.MSK company it is possible to order a glazing of turnkey roof balconies. Our experts will also carry out repairs and complete restoration of the integrity and integrity of the roof. Call the master, who will check the quality of the existing structures and determine the amount of upcoming work.

Russia, Moscow, 2nd St. Engineering, 27 p6.

Seven days a week, from 8:00 to 20:00.